Greenoz Ventilation System not only specializes in designing high-quality cold rooms but also offers comprehensive guidance for those looking to undertake cold room projects themselves. Understanding the proper cold room installation process is crucial to ensure efficient cooling, long-term durability, and safety. Our company provides detailed instructions on selecting the right insulation panels, refrigeration units, and electrical components, making the assembly process easier for both beginners and experienced users.

What Is a Cold Room?

A cold room is a temperature-controlled insulated space designed to store products such as fruits, vegetables, dairy items, meat, pharmaceuticals, and other perishable goods. The purpose of a cold room is to maintain a consistent low temperature and humidity level, preventing spoilage and extending shelf life. Proper cold room installation ensures energy efficiency, uniform cooling, and reliable performance.

Materials Required for Cold Room Installation

- PUF Insulated Panels – Used for walls, ceiling, and floor to reduce heat transfer and maintain consistent internal temperature.

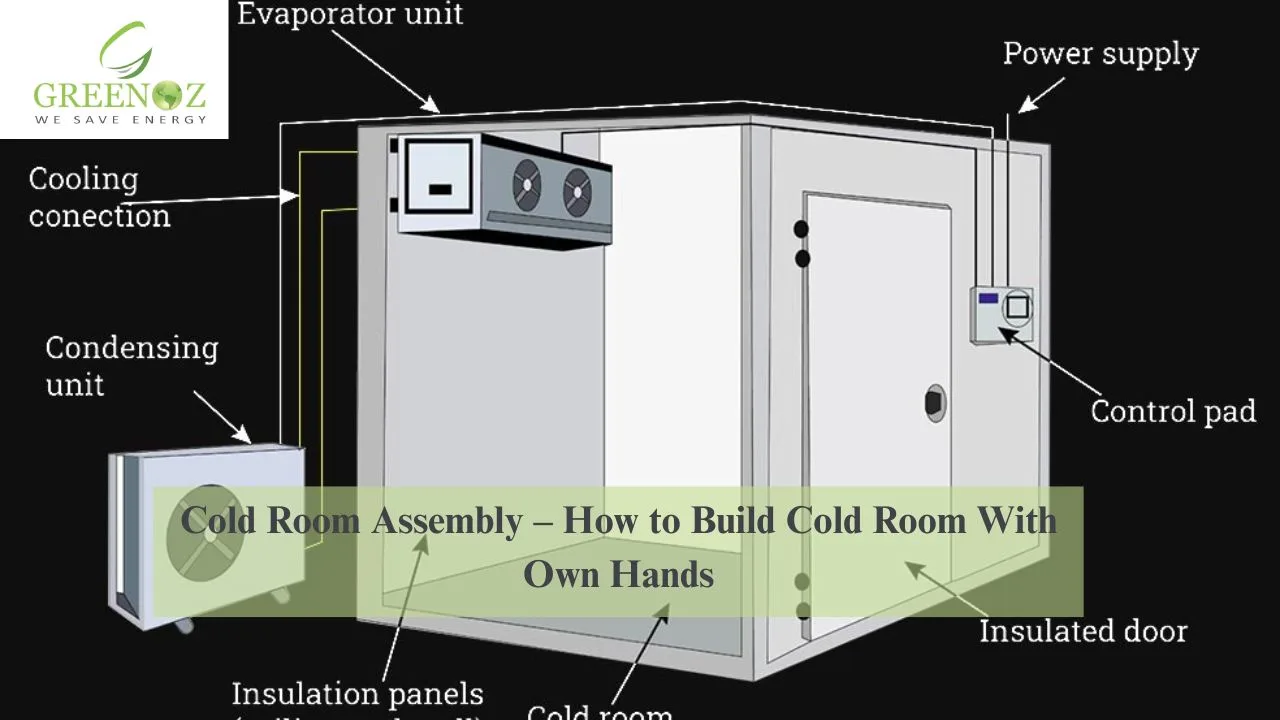

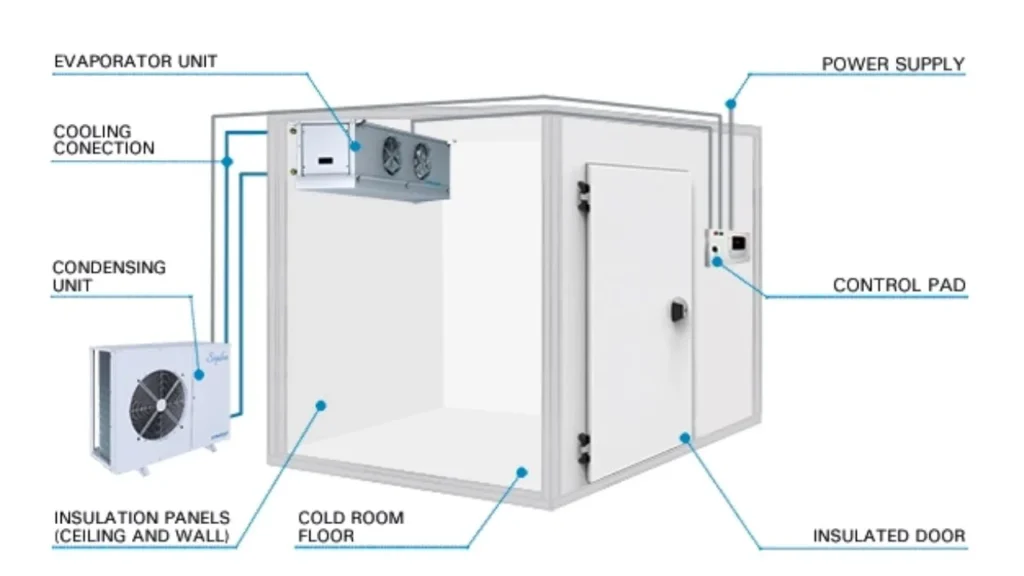

- Refrigeration Unit – Includes compressor, condenser, and evaporator to control and maintain the required cooling level.

- Cold Room Door – Insulated hinged or sliding door with airtight sealing to prevent temperature loss.

- Temperature Controller & Sensors – Helps monitor and regulate the internal temperature accurately.

- Electrical Components – Wiring, control panel, switches, and lighting for safe and smooth operation.

Also Read : What is the Ideal Temperature for Commercial Freezers?

Step-by-Step Cold Room Assembly Process

Building a cold room requires careful execution of each step to ensure proper insulation, cooling efficiency, and long-term durability. Below is a detailed yet easy-to-follow guide for assembling your cold room:

- Floor Preparation: Start with a level, sturdy floor that can support the weight of stored goods. Many cold rooms use insulated floor panels made of PUF (Polyurethane Foam) to minimize heat transfer from the ground.

- Wall Panel Installation: Install the insulated wall panels using cam-lock systems or fasteners. Ensure that the panels are aligned correctly and that all joints are tightly sealed.

- Ceiling Panel Installation: After the walls are in place, position the ceiling panels. Make sure all joints between the ceiling and walls are sealed carefully.

- Refrigeration System Setup: Install the refrigeration components, including the evaporator inside the cold room and the condenser outside in a ventilated area. Connect refrigerant piping and insulation properly.

- Electrical and Control Panel Connection: Connect all electrical wiring for lighting, sensors, and temperature control systems. Install temperature controllers to monitor and regulate internal temperatures.

- Door Installation: Attach the insulated cold room door with airtight seals and secure locking mechanisms. Doors must be properly aligned to avoid air leakage, which is essential for maintaining temperature and reducing energy consumption.

- Testing and Commissioning: Perform a trial run to check the cold room’s performance. Monitor temperature stability, refrigeration efficiency, and door sealing.

Size of a Cold Room

The size of a cold room depends on the type and quantity of goods you plan to store. For home or small business use, a compact room of 6–10 feet may suffice. For commercial or industrial purposes, larger rooms with multiple compartments are preferred. During cold room installation, planning the size helps determine insulation thickness, refrigeration capacity, and panel requirements, ensuring efficient cooling without excessive energy consumption. Referring to a cold room diagram can make this process easier, allowing you to visualize the layout, optimize space, and ensure efficient cooling without unnecessary energy consumption.

Why Choose Greenoz Ventilation System?

Greenoz Ventilation System is a trusted name in the field of temperature-controlled storage solutions, known for its high-quality products and customer-focused approach. Our company specializes in cold room installation and cold storage installation, offering practical guidance and reliable machinery for businesses and individuals alike. We ensure that every cold room is designed for maximum efficiency, durability, and safety. We provide solutions that are easy to assemble, energy-efficient, and adaptable to different storage needs.

From selecting the right insulation panels to installing refrigeration systems and control units, the team at Greenoz Ventilation System delivers expert support at every step. Choosing Greenoz Ventilation System means partnering with a company that prioritizes quality, precision, and customer satisfaction, helping you build a cold room that performs flawlessly for years.